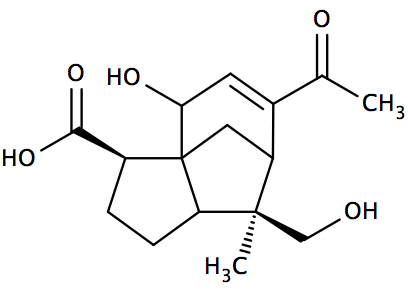

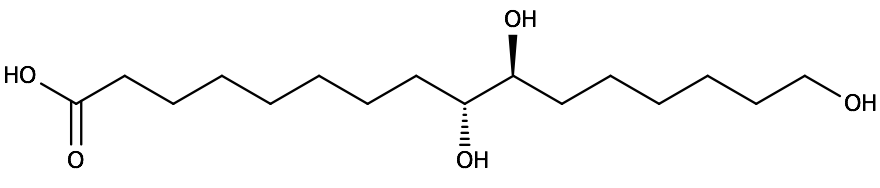

Shellac is the purified form of the natural resin lac. It is excreted by Kerria lacca and collected in its raw form from different trees in India, Burma, Thailand and China. After collection, it is grinded, mechanically separated from wood pieces and other contaminants and washed with water. Seed lac, as it is called in this stage of purification, is a complex mixture of shellolic acid, aleuritic acid and other aliphatic and alicyclic acids, wax and colouring components.

|

|

| Shellolic Acid | Aleuritic Acid |

The European Pharmacopoeia differentiates between four types of shellac: wax-containing shellac, dewaxed shellac, bleached shellac and dewaxed and bleached shellac.

The simplest form of purification is by filtration of the molten seed lac. Subsequently, the melt is drawn to sheets and flakes are obtained after cooling. This type is called wax-containing seed lac. Additionally, the colouring substances are not removed.

Bleached shellac is obtained from seed lac by dissolution in an aqueous solution, filtration and bleaching with hypochlorite. Subsequently, the shellac is precipitated by the addition of mineral acids.

The most gentle purification method for shellac is the solvent extraction method. This is especially suitable for shellac that is intended for pharmaceutical, food or cosmetic application. Firstly, the seed lac is dissolved in ethanol and impurities and the waxes are removed by filtration. This grade is called dewaxed shellac. Secondly, the remaining colourants can be removed by activated carbon. Finally, the ethanol is removed (and recycled) and dewaxed shellac flakes of light colour are obtained.

The Chemistry of Shellac

Shellac is an amorphous, hard and brittle resin with a molecular weight of around 1000 Da. As mentioned above, it is a complex mixture of esters and polyesters of polyhydroxy acids. The main components are shellolic acid, aleuritic acid and other aliphatic and alicyclic acids. Despite its rather low molecular weight, shellac has excellent film forming properties. It is soluble in most alcohols, like ethanol, methanol and isopropanol, and insoluble in most hydrocarbons. Normally, shellac is not soluble in water but clear solutions are obtained in warm water that has been alkalized with, e.g., ammoniac or triethanolamine. Even though it is insoluble in neutral and acidic aqueous solutions, it can be dissolved in acetic and formic acid.

Depending on its source and purification method, shellac grades can vary substantially in their molecular composition (wax content) and particularly in their colour (from white and light yellow to dark brown). However, modern industrial purification methods guarantee a stable quality that can be used for pharmaceutical, nutritional and cosmetic products.

The Safety of Shellac

For more than 2000 years, Lac has been used in colours and lacquers in China and India. It is GRAS listed by the FDA and approved as a food additive in the EU. Shellac is widely used in industrial, food, cosmetic and pharmaceutical applications. The acute toxicity was determined to be above 5 g/kg (in rats) and shellac did not exhibit any mutagenicity or teratogenicity. Thus, its use in pharmaceutics, food and cosmetics can be seen as safe.

Applications of Shellac

Due to its film forming properties and its low vapour and oxygen permeability, shellac is used as a coating material for moisture sensitive drugs in the pharmaceutical industry. An ethanolic shellac solution is suitable as a primary coating for moisture sensitive tablet cores. As a second step, the main aqueous coating, like MANTROCEL® or other functional aqueous coatings, are applied. Shellac has a low solubility at a low pH and therefore, can be used as a natural enteric coating or for sustained release formulations.

Since shellac has a very good safety profile and is of natural origin, it is an excellent excipient for food and nutritional supplements. It can be used as a glaze for confectioneries, protective coatings for fruits or as a coating for nutritional supplement tablets and capsules.

In the cosmetic industry, shellac is used as a film former and gloss agent in haircare formulations. Moreover, it is an excellent thickener, stabilizer and adhesive in a variety of cosmetic products like mascara, nail polish and body paint.

These odourless and tasteless finishing agents provide many benefits:

- Brilliant gloss

- Enhanced shelf-life

- Scuff resistance

- Adhesion and sealing for nut centres

- Anti-sticking agents for jellies and gummies (starch, pectin or gelatin based)

- Fat barriers

- Moisture resistance

- Anti-blocking for panned pieces

Available Grades

We offer ethanolic and aqueous shellac resins and glazes for film and seal coating for the pharmaceutical and food industry from Mantrose. Other grades for application in personal care are also available.

CERTIFIED® Pharmaceutical Glaze - Industry standard for over 50 years for high gloss finishing.

CRYSTALAC® - Shellac glazes provide a consistent high quality gloss from pan to package, without overnight tray drying.

CRYSTALAC® Zein - A vegetable-based protein, which can be used as a general film coat or enteric coating for pills and other encapsulated foods and drugs. GMO-free, clear, odourless, tasteless and water-insoluble.

CERTISEAL® coatings increase film build rates and produce a superior finish.

CERTISEAL® 100 A. Shellac undergoes aging because it contains free carboxylic and hydroxyl-groups that allow selfesterification. Aging leads to a loss in solubility, an increase in the glass transition temperature and a decrease in the acid value. In the case of pharmaceutical coatings, this can result in an undesired change of the drug release profile. Certiseal 100 A is an ammoniacal aqueous shellac solution that is far less prone to aging than shellac from ethanolic solutions. After drying, it forms a shellac ammonium salt that is more stable than free acid. Moreover, as an aqueous solution, it is easier to handle as a solvent-based shellac coating solution.